AVAILABLE PROCESSES

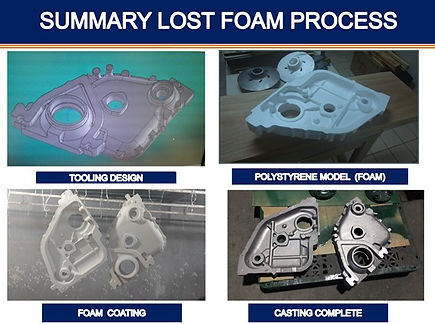

MOLDING AND CASTING IN LOST FOAM PROCESS

The Lost Foam process involves creating a Styrofoam model that is placed in a molding box and surrounded by compacted foundry sand. Molten metal is then poured into the cavity, instantly burning off the foam and leaving an accurate replica of the desired part. After the metal cools and solidifies, the casting is removed from the sand and the box is disassembled for reuse. This method allows for the fabrication of complex parts with fine details and reduces manufacturing costs and times by eliminating the need for a solid casting model.

HEAT TREATMENT AREA

Heat treatment is key in the industry to alter the properties of metals. It begins with heating the material in a specialized oven, followed by a holding period at a specific temperature to allow internal transformation. The material is then cooled depending on the desired effect, such as increasing hardness or improving toughness. The ovens provide controlled conditions to ensure process precision. In summary, heat treatment is essential to adapt metals to various industrial applications.

PROCESSES

CNC MACHINING

At VIDAMEGHEX we have several alternatives for CNC machining, we take advantage of our horizontal and vertical machining centers, 5 axes and CNC lathes. In the machining area we have 2 departments, the design and manufacturing of toolings to later use these in the Lost Foam process and the second department which is the machining of the cast parts or castings. We have 5-axis CNC machining which allows us to work with complex geometries, ensuring precision, quality and reducing set-up times for each operation. Integrating machining after casting ensures quality and reduces external claims. Our comprehensive approach makes it easy to complete complicated parts and challenging projects efficiently and cost-effectively.

EXPANDED POLYSTYRENE INJECTION

Expanded polystyrene injection (EPS) involves heating the EPS beads to expand them using steam and then injecting them into a mold, where they are compressed to form the desired product (foam piece). After a cooling period, the product is removed from the mold and moved to the painting area. In this area, the so-called trees or joints of the foam pieces are made and they are covered with a special coating. Once the trees are finished, they go to the molding and fusion area, where these trees, which already contain several pieces of foam, are placed in tubs that will later be filled with sand and compact the polystyrene tree. Once the process is finished, the previously molten metal is poured into each vat, which passes through the polystyrene tree, burning the material and taking the shape of the space left by the piece when it evaporated from the polystyrene. Thus in the end the tree that was initially made of polystyrene is transformed into metal pieces or castings.

Quality and compliance

We comply with national and international standards to guarantee the quality of our services. Our commitment to excellence drives us to follow the highest standards in each project. You can trust us to meet and exceed your expectations. We work with integrity and dedication to provide you with exceptional results. Throughout the production process we have traceability tools between processes to always have real information on the status of castings and machined parts.

Featured Services

At VIDA MEGHEX, we specialize in offering a wide range of high-quality services to meet the needs of our clients. Our commitment to excellence and attention to detail sets us apart in the industry. Explore some of our featured services below and feel free to contact us for more information.

Shot Blasting services

Our shot blasting service uses cutting-edge technology to effectively remove dirt, rust and impurities from metal surfaces. With our experience and specialized equipment, we guarantee exceptional results and optimal preparation for manufacturing and finishing processes.

Metalurgic laboratory

We have a fully equipped metallurgical laboratory to perform exhaustive testing and analysis of materials. Our team of experts uses advanced techniques to evaluate the quality, strength and properties of metals, allowing us to offer accurate and reliable solutions to our customers.

Various Conventional Machining

Our conventional machining service offers personalized solutions for the manufacturing of metal parts and components. We use traditional techniques and high precision tools to ensure quality and precision in each project. Trust our team of highly trained professionals to meet your exact requirements.